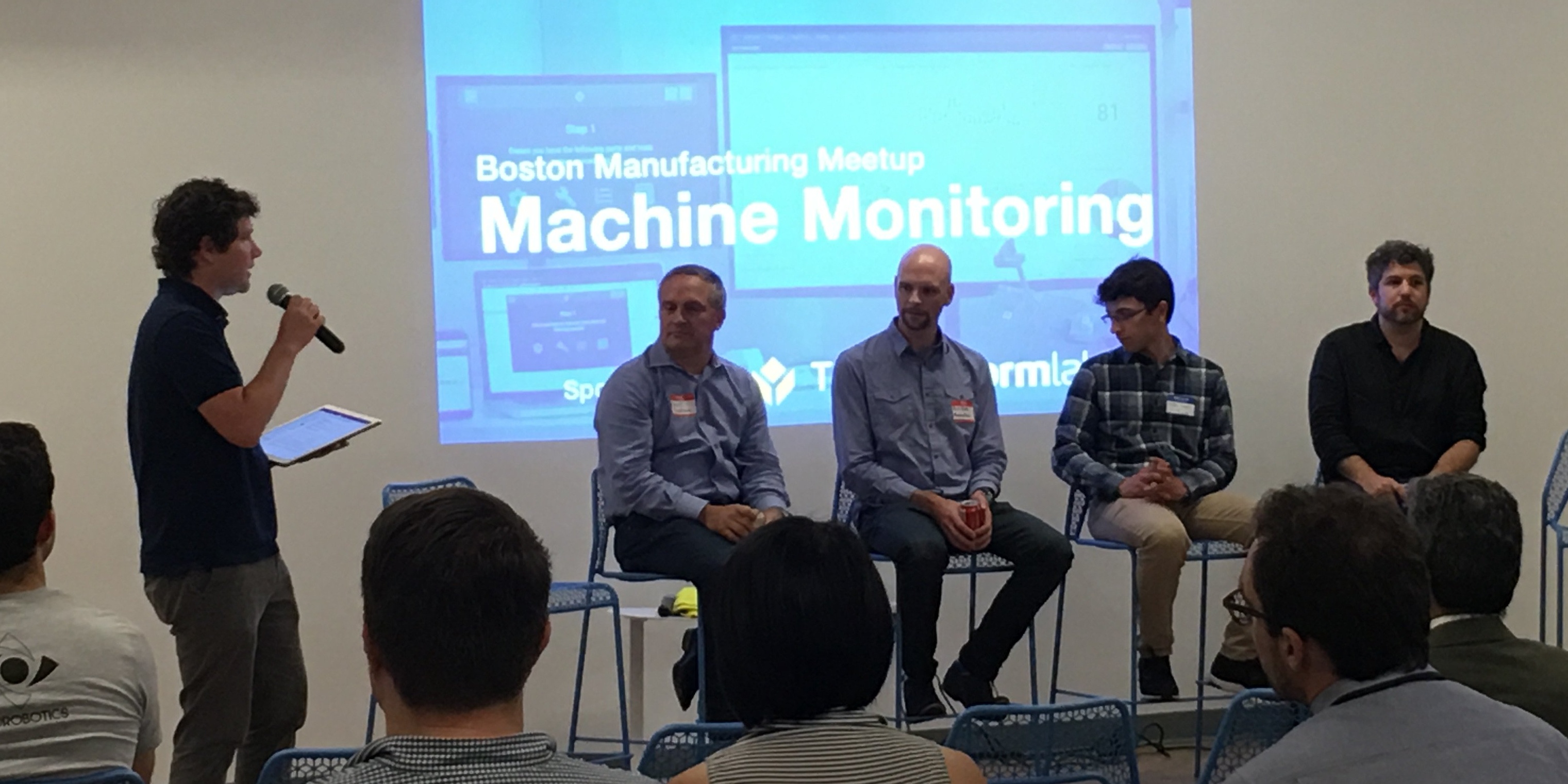

Machine Monitoring is a hot topic among the Industry 4.0 buffs. What good is having the latest machines in your shop floor if you don’t know what is going on with them? This month's Boston Manufacturing Meetup, hosted along with Formlabs, dug into this question. We had a panel with the CEO of Machine Metrics, the VP and GEM of PTC Connected Solutions, the Print Production Manager of Formlabs and the CEO of Tulip. Each one gave their unique perspective on the topic from their company's point of view. Below are some of the most relevant insights from the panel.

Machine Monitoring means different things to different people

When evaluating a machine monitoring solution, you need to ensure it adds value to all the stakeholders. Doing so entails realizing that machine monitoring means different things to different people. Your maintenance team, for example, cares about downtime/maintenance metrics; operators care about interfacing with the systems and so on. Unless the solution you choose caters to all stakeholders' interests, you won’t have the buy-in you need to be successful.

To ensure success, tie your machine monitoring initiative with a business use case

Machine monitoring projects often fail because they lack organizational buy-in.To secure this buy-in, you need to ensure it adds value to everyone. However, it is also essential to tie your machine monitoring initiatives to a business use case so that the right incentives are in place for everyone to get behind the initiative. While every company is different, all panelists agreed that Production Visibility is usually an excellent place to start.

Data collection is just the tip of the iceberg

Though production visibility is a worthy starting point, data collection shouldn’t be the end goal of your machine monitoring initiatives. Instead, the goal should be to collect meaningful and actionable data that can be used to improve your operations. Each industry and factory might have different metrics that are relevant for them, so when evaluating software providers, make sure they offer enough flexibility to determine the reports and dashboards you want to measure and track. Also, be careful of built-in benchmarking, as it might mislead you to compare yourself to the wrong industries.

Make sure the machine monitoring data you collect can talk with other systems

When you implement a machine monitoring solution, you want to make sure the data you receive doesn’t end up siloed and unable to connect with your other systems. Otherwise, you won't be able to extract the real value out of the data you collect. When evaluating machine monitoring solutions ask how easy it is to integrate with your other systems. Does the product offer connectors or do you need to develop them from scratch? Unless you ensure you can integrate all your data, you won't be able to leverage it.

Look beyond Overall equipment effectiveness (OEE)

For many, machine monitoring is all about OEE - Overall equipment effectiveness. While this is an important metric to track, it is also backward looking. When thinking about the relevant parameters you want to follow, make sure you think beyond descriptive metrics (which tell you what is going on) to diagnostics analytics (which tell you why) to predictive analytics (which tell you what will happen) to prescriptive analytics (which tell you how to improve).

Machine monitoring is about much more than machine metrics

Humans run Even the most sophisticated machines, so unless your machine monitoring solution monitors human activity, you will never get the full picture of what is going on your shop floor.

The best machine monitoring solutions go beyond machine metrics - they take into account human metrics.